Made in Slovakia

Made in Slovakia

ISO 9001

ISO 9001

Made in Slovakia

Made in Slovakia

ISO 9001

ISO 9001

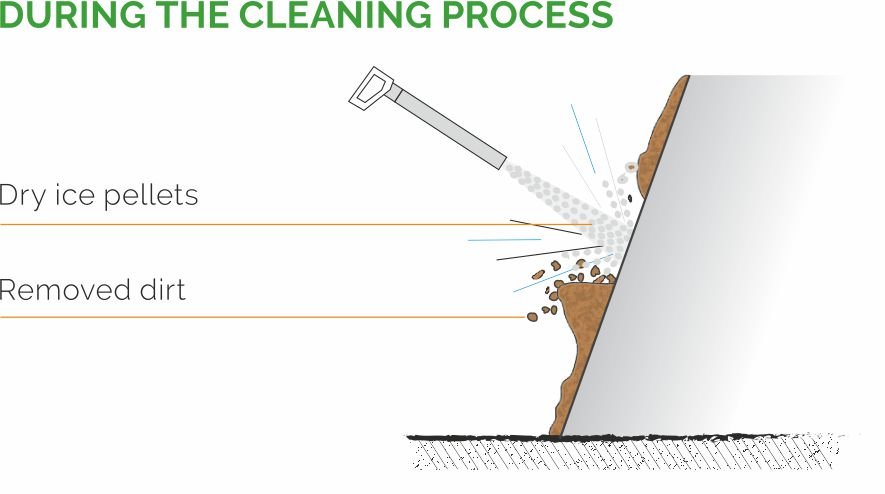

The cleaning process applies a combination of three phenomena.

The impact velocity of dry ice pellets on a contaminated surface can exceed even the speed of sound.

Contaminated layers become brittle after rapid cooling and are gradually released from the cleaned surface.

After contact with the contaminated surface, the pellets change their physical state and become a vapour, perfectly removing any contamination

Cleaning – dry ice blasting is a modern industrial cleaning method.

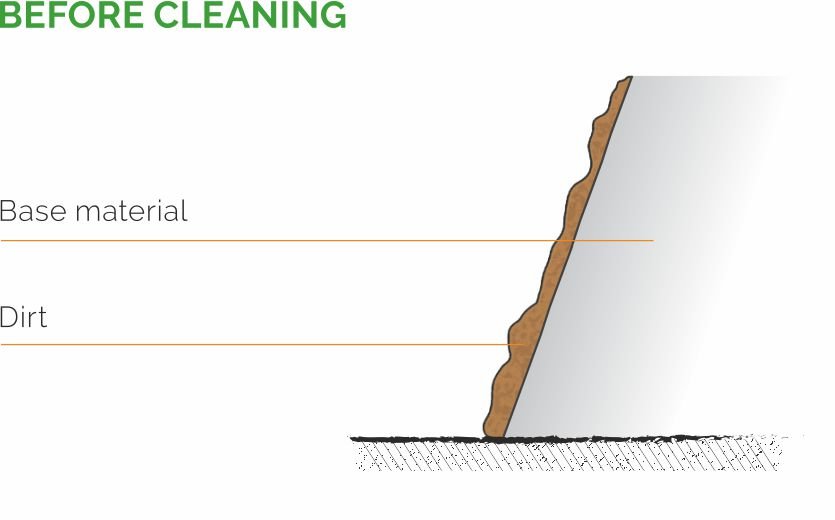

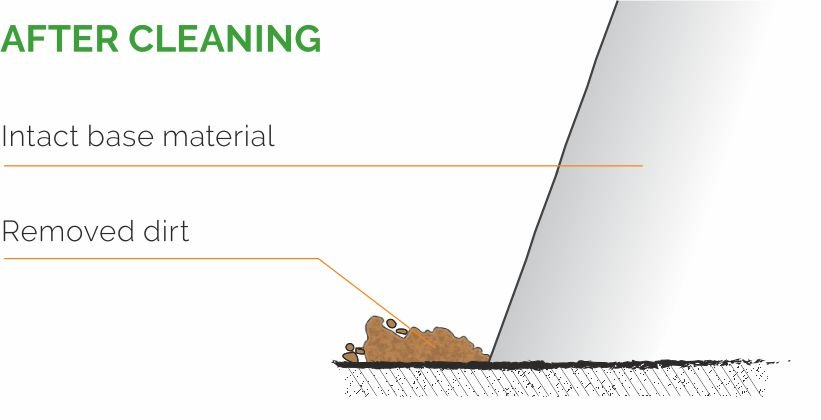

The cleaning process applies three basic phenomena: kinetic energy, thermal shock, and sublimation. The process only removes residues and no secondary waste is produced. Dry ice blasting is a cleaning method which is effective, gentle on the cleaned materials and environmentally friendly. Dry ice lets you gently and ecologically clean deposits of sediment and residue without needing to dismantle any of your equipment. You therefore save time and considerable monetary costs.

Dry ice is known to inhibit the growth of bacteria. The dry ice cleaning process also stops the growth of fungi and spores and reduces the presence of other biological contaminants. It is also non-toxic, odourless and suitable for any surfaces – metal, wood and concrete, even on fine wood grains, glass or textiles.

What is dry ice?

Dry ice is the solid state of carbon dioxide (CO₂) formed at a temperature of -79 °C.

Carbon dioxide is naturally found as a gas on Earth. It is non-toxic and odourless, and often used to saturate drinks to give them a fresh taste and prolong consumption. Dry ice is also used in the food industry to cool food or applied in health services.

The following accessories are required for dry ice cleaning: