Made in Slovakia

Made in Slovakia ISO 9001

ISO 9001 Made in Slovakia

Made in Slovakia ISO 9001

ISO 9001 Choosing of a right method is important

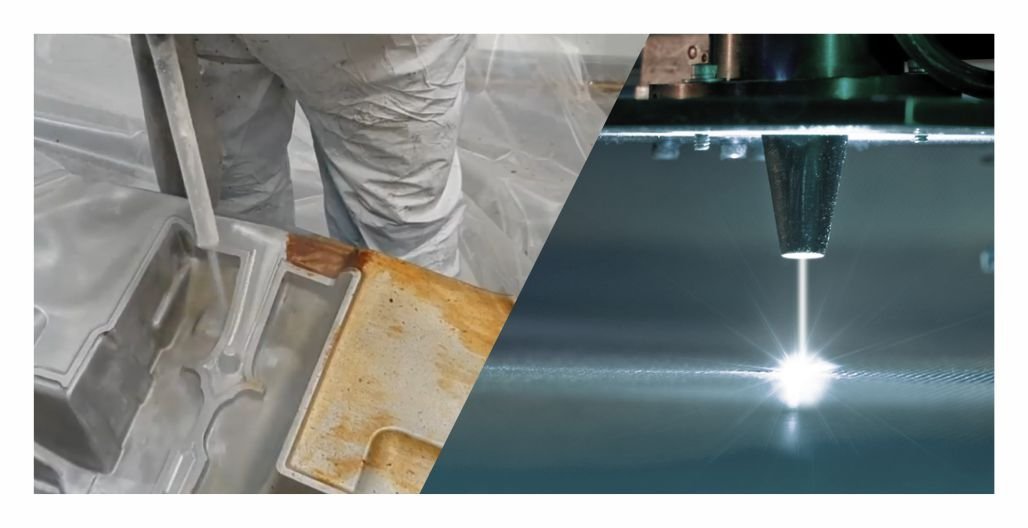

Choosing of a right method is important Professional cleaning of industrial equipment, molds or machine parts must be thorough, efficient, and first of all gentle. High quality and expensive machine must not be damaged. These requirements are met by dry ice cleaning technology and laser cleaning.

Do you have problem with efficient and time-saving cleaning of components or entire assemblies? Laser cleaning or dry ice cleaning are the most modern, environmentally friendly and resource-saving cleaning methods. They are characterized by a wide range of their application. They do not generate other waste materials, such as sand, glass beads or water residues. They can even be used during production, without a need to shut down and dismantle the equipment. So how to choose the right technology?

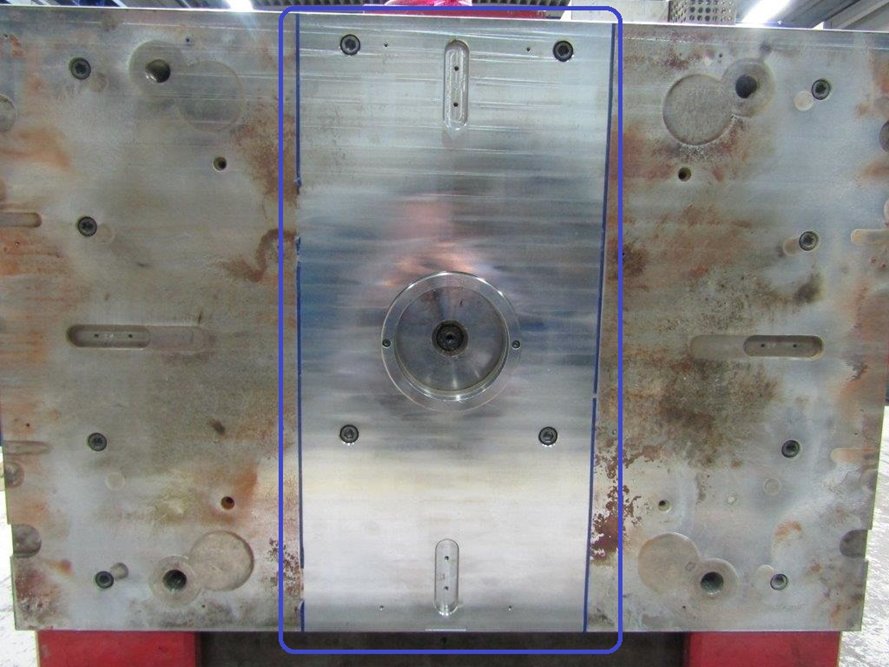

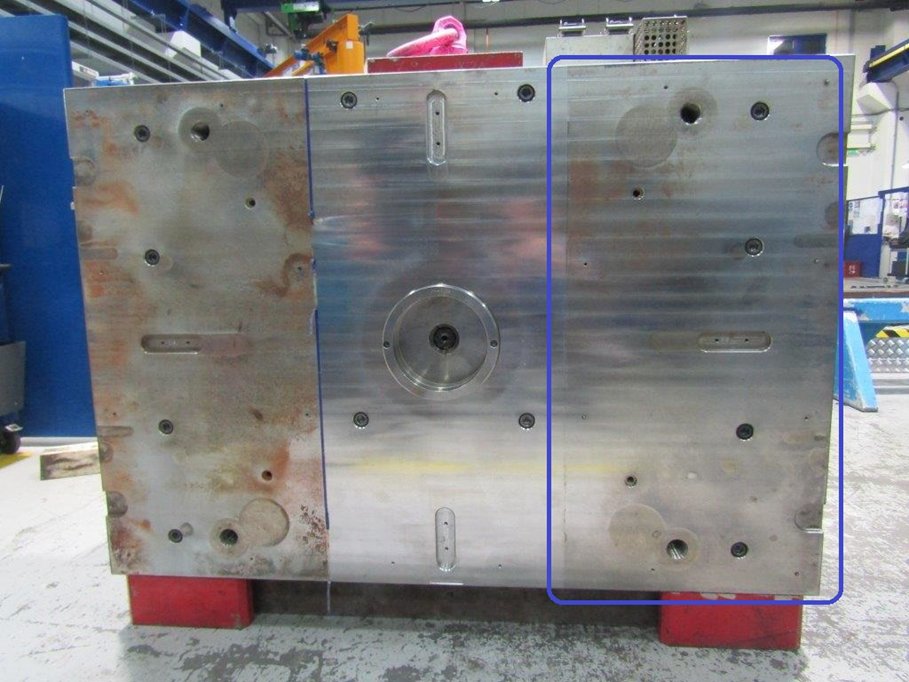

Case study: Comparison of laser cleaning technology vs. dry ice cleaning. Range: 1200 x 600 mm.

Case study: Comparison of laser cleaning technology vs. dry ice cleaning. Range: 1200 x 600 mm.

LASER CLEANING

LASER CLEANING

Laser cleaning is technologically demanding and requires a prudent way of working. The laser beam emits very strong but short laser pulses, and thus the layer of dirt or the cover layer is removed by evaporation. These laser pulses cause very small thermal impacts on the base material. Cleaning is performed in a very gentle way and without damage. During the operation, the laser is almost silent and can be integrated directly into the production process, taking into account the relevant safety measures. It is possible to remove individual thin layers between 0.001 mm and 1 mm. However, this method has certain limitations - it is not suitable for all surfaces - for example, wood, glass or plastic. Laser cleaning is not very suitable for surfaces or objects with difficult - to - see cracks (pipes, tubes, etc.)

DRY ICE BLASTING

DRY ICE BLASTING

A high level of surface efficiency can be achieved by using the dry ice blasting method. Depending on the working pressures used, the nozzle geometry and the type of contamination, it is possible to clean more than one square meter per minute. This method is suitable for almost all surfaces, including wood and plastic. It is possible to remove impurities with a thickness of 1 mm to 10 mm in a very simple way by this innovative process. Dry ice pellets hit the surface at almost the speed of sound, removing dirt without use of chemical or abrasive materials. Unlike many other blasting methods, only the remaining dirt will remain as a residue. This method does not cause any damage to active electrical or mechanical parts. There is no risk of ignition or fire during the cleaning process. It is environmentally friendly method, because it does not contain any solvents or secondary harmful substances.

Laser (5 min) vs. / CO2 (3min):

Laser vs CO2:

Is dry ice cleaning method right for you?

Is dry ice cleaning method right for you?

We will prepare time and cost study free of charge on the items you bring to us. We will select the most suitable combination of the equipment with necessary parameters. You will find out which technology is more suitable for a given application. We will prepare you practically for your tasks and provide you with specific tips and instructions on how to increase profitability with dry ice blasting technology.