Made in Slovakia

Made in Slovakia ISO 9001

ISO 9001 Made in Slovakia

Made in Slovakia ISO 9001

ISO 9001

Surface rust can cause considerable damage to car owners. All vehicles are made of metal and are prone to surface rust. If it is not removed, it can spread and cause many problem. It is ideal to prevent it - take care of scratches on the paint, regularly wash and wax the body, remove mud, salt and dirt, do not forget to clean the car chassis, because this is a place affected by rust most often.

Surface rust removal by sandblasting

Surface rust removal by sandblasting

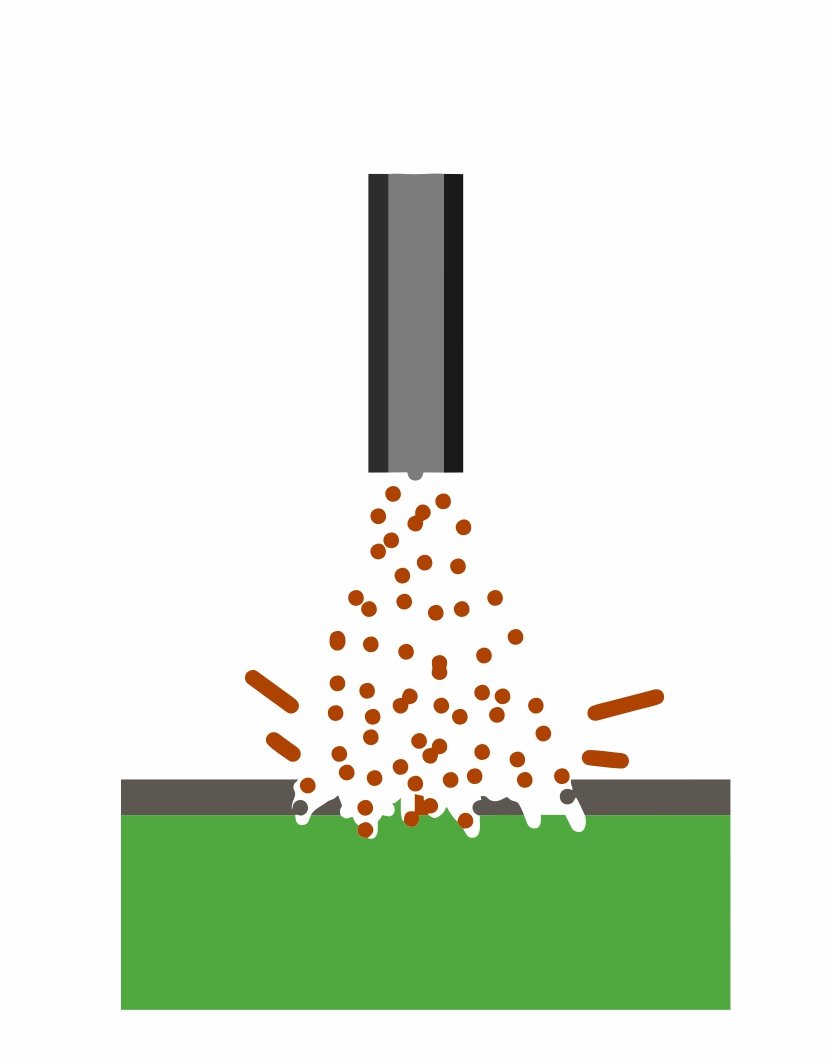

Sandblasting is one of the most effective ways to remove surface rust when renovating a car. However, despite of its effectiveness, it has disadvantages:

- sandblasting can be extremely aggressive; you risk destruction of parts and reduction of their service life,

- sand gets into every corner of the car - to the ball joints, connecting rods, etc.;

- you probably won't be able to handle sandblasting yourself, especially due to lack of equipment and space;

- greasy material must be degreased, as grease causes that the abrasive material loses its effectiveness and flowability,

- sandblasting causes heating of the metal surface and its deformation.

"More suitable alternative is dry ice blasting in combination with the abrasive material."

"More suitable alternative is dry ice blasting in combination with the abrasive material."

Dry ice cleaning

Dry ice cleaning

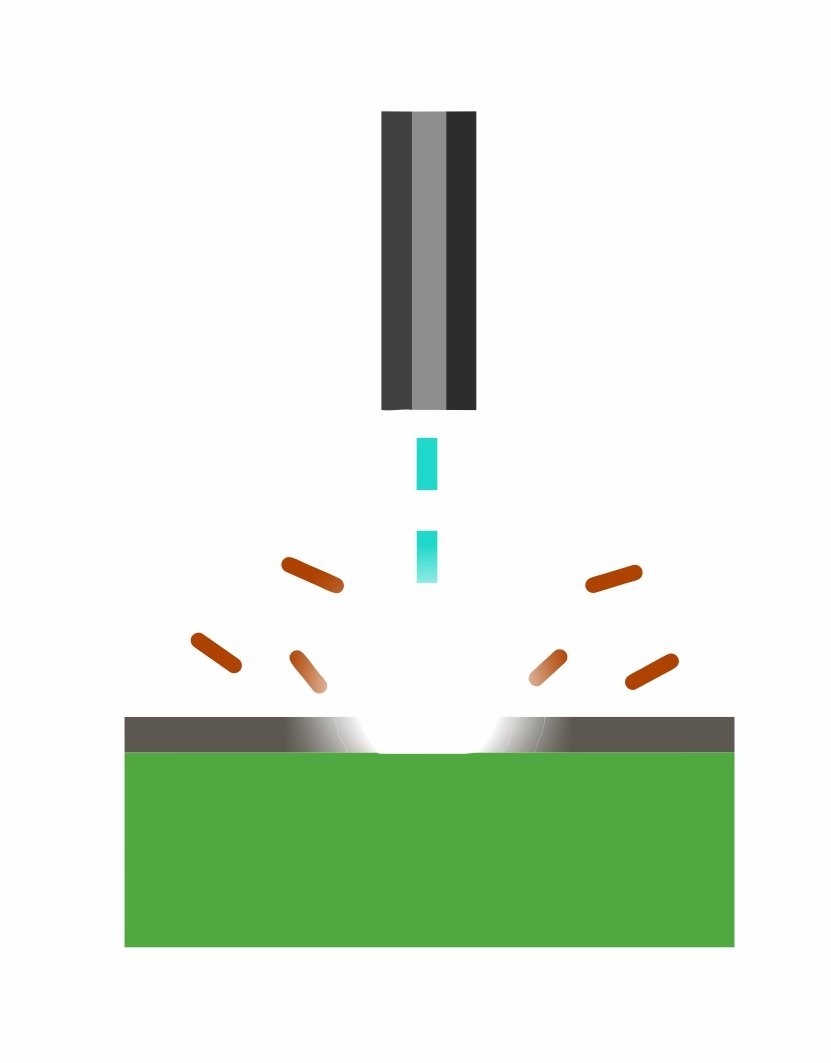

Surface rust removal can be performed using dry ice cleaning technology in combination with an abrasive material. This method is environmentally friendly, non-chemical, and non-toxic. It is an important alternative to the original cleaning procedures - sandblasting, dry cleaning, etc. Blasting with dry ice causes significant time savings, as it is not necessary to disassemble and subsequently reassemble the parts. When cleaning with dry ice, the cleaned metal surface is not overheated and subsequently deformed. Other advantages:

- significant reduction in the amount of abrasive material compared to sandblasting (depending on the application and setting of the device),

- less secondary waste than in case of traditional sandblasting due to sublimation of dry ice,

- abrasive blasting according to the highest possible standards of environmental responsibility,

- abrasive or non-abrasive cleaning using a single machine

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

IC 310 S │ The most versatile dry ice blasting machine

The professional dry ice blasting machine IC310 S is our most powerful device, enabling the widest possible range of cleaning. The machine works from the finest microparticles cleaning to aggressive blasting in the most demanding applications. Thanks to the patented pellet grinding system, pellet microparticles are created, which can be used to remove dirt from very sensitive surfaces, such as a surface of highly polished molds, pneumatic and electrical wirings, machine control panels, as well as the car interior. One button on the control panel switches the pellet microparticle cleaning mode to cleaning with standard 3 mm granulate to remove heavier contamination.

IC 310 S as well as other ICS devices have a built-in passage system in the neck of the hopper as a standard. Our machines do not freeze. Ergonomically shaped blasting gun is very durable, safe, and easy to operate. It requires only minimal maintenance costs even in demanding operating conditions.