Made in Slovakia

Made in Slovakia ISO 9001

ISO 9001 Made in Slovakia

Made in Slovakia ISO 9001

ISO 9001

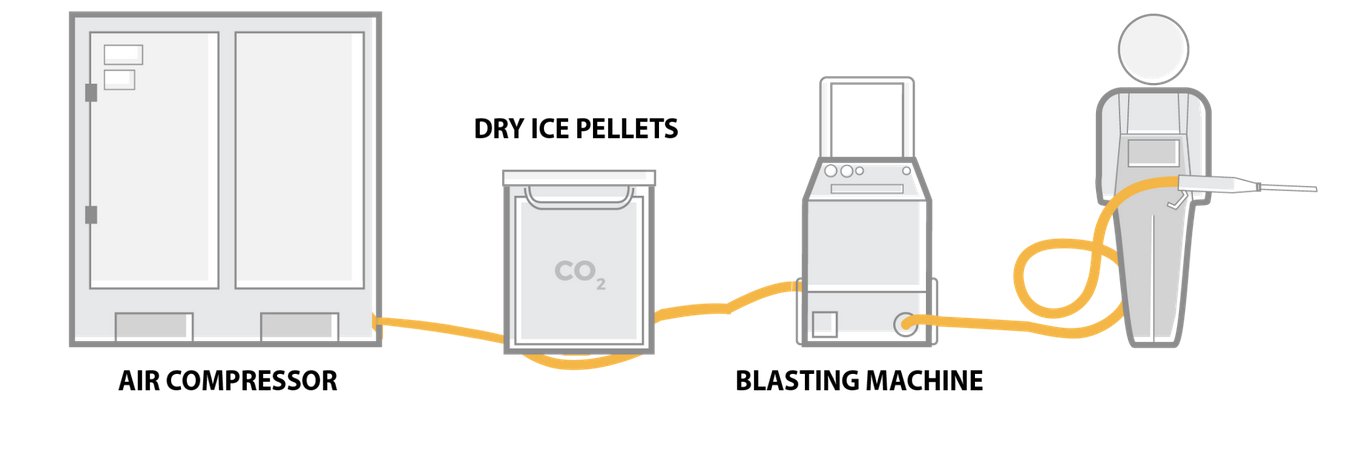

To run dry ice blasting smoothly, the compressed air should meet certain pressure, flow, and dryness requirements.

In many plants, the quality of compressed air is not sufficient, which is also reflected in the dry ice blasting process, as the effect of thermal shock in dry ice blasting also depends on the temperature difference between the dry ice pellet and the contaminant. Diesel compressors often produce hot and humid air which can hinder performance of the dry ice blasting equipment. Therefore, when using a portable diesel compressor, it is important to make sure that you are using really dry air.

Where does the moisture in compressed air come from?

Compressed air is produced by compressing atmospheric air, which always contains a certain amount of water. This compressed air can cool on the way to the appliances and the water vapour can partially or completely liquefy and cause damage. A dew point is the key. The warmer the air, the more steam it can hold before the steam starts to condense. Water droplets will begin to form in the air once the air cools to a temperature called the dew point. When the air is at dew point temperature, it is completely saturated with water vapour (the relative humidity reaches 100%). When the air cools below the dew point temperature, the water vapour in the air turns to water. However, the dew point temperature of the air is not always the same. It depends on how much water vapour is in the air, i.e. how humid the air is. Therefore, if you want to avoid humidity problems in compressed air, choose a suitable dryer. They help to reduce the air temperature, the amount of accumulated moisture and filter out debris to prevent freezing and damage to the dry ice blasting equipment.

The aim of air drying is to reduce the amount of water vapor in the air to bring the dew point to the desired value. For compressed air, the term pressure dew point is used, i.e. the temperature at which the vapour condenses at a given pressure. In order to use compressed air at normal temperatures, it is advisable that its pressure dew point is 10° lower than the temperature in the plant or workshop.

Regardless of your environment, it is important to understand how hot or wet air affects performance of your dry ice blasting equipment. When you can reduce or eliminate excess moisture, performance of your equipment will improve dramatically.